LYF / LAF

Hydraulic Prefill Valve

LYF & LAF Sandwich type, two different materials.

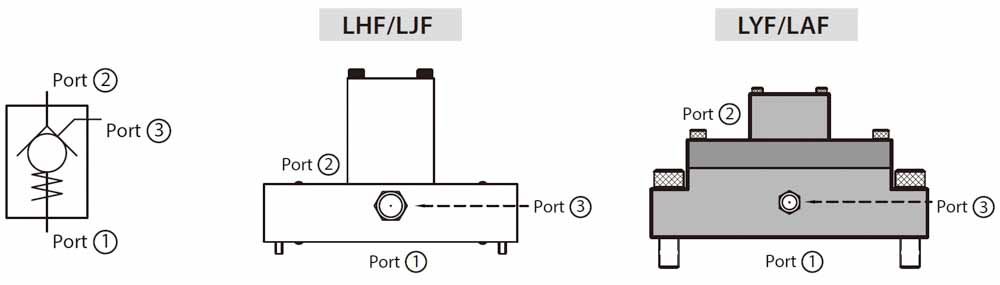

━Symbol

━DESCRIPTION

The working principal of prefill valve is like pilot-to-open check valve. It allows free flow from the port 2 to port 1 and blocks flow in the opposite direction. Pressure at pilot port (port 3) will open the valve from port 1 to port 2.

In case any shock, noise and system damage, please make sure it has already completely decompression at port 1 then pilot to open the prefill valve allowing flow from port 1 to port 2. When pilot port is blocked, prefill valve acts like a large

capacity check valve. LINS hydraulics provides two types and two materials prefill valve, including sandwich and flange mounting type, alloy steel (SCM440) and cast iron (FCD50).

It can be directly fitted on the cylinder cap end or mounting on piping flange in the hydraulic systems. The operating pressure up to 400 bar (5800 PSI), capacity up to 15000 LPM (4000 GPM).

━FEATURE

l Compact size & easy installation.

l High pressure, high durability.

l High capacity and low-pressure loss.

l Sandwich and flange mounting type.

l Two materials, alloy steel and cast iron.

l Directly mount on cylinder cap end.

█ ORDER CODE

|

LYF |

- |

100 |

|

① |

② |

①: Series

LYF: Flange mounting type, SCM440 material.

LAF: Flange mounting type, FCD50 material.

②: Valve size

32 – 250

(See dimension table for reference)

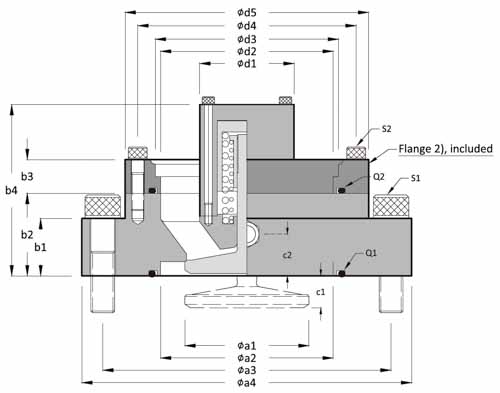

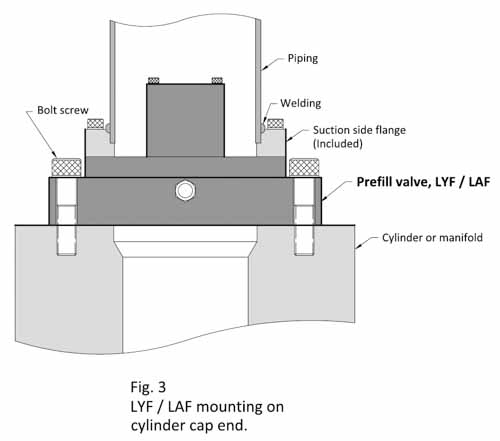

█ LYF / LAF DIMENSIONAL DRAWING

Notice:

1. Attention for poppet working space c1.

2. LINS offer the suction side flange with LYF and LAF prefill valve. For LHF and LJF series, flange must order separately.

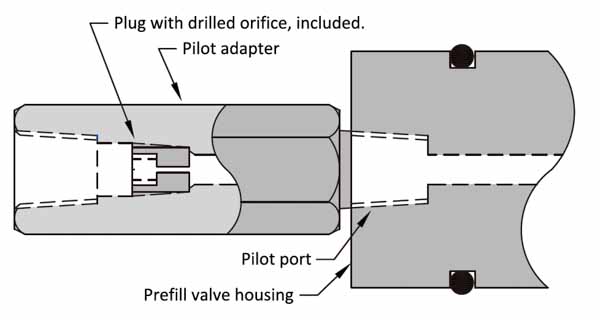

3. All LINS prefill valves including a pilot port adapter with orifice plug, see table for orifice and plug size.

█ LYF / LAF Dimension Table (mm)

|

p |

Q1 |

Q2 |

S1 |

S2 |

Model |

øa1 |

øa2 |

øa3 |

øa4 |

b1 |

b2 |

b3 |

b4 |

c1 |

c2 |

ød1 |

ød2 |

ød3 |

ød4 |

ød5 |

d6 |

|

|

1/4" PT |

AS228 |

AS228 |

4-M16x45L |

4-M10x35L |

|

LAF32 |

34 |

48 |

103.2 |

130 |

24 |

47 |

20 |

65 |

7 |

15 |

33 |

51 |

61 |

92 |

111 |

62 |

|

1/4" PT |

AS236 |

G80 |

6-M16x55L |

6-M12x40L |

LYF50 |

LAF50 |

53 |

72 |

146 |

180 |

33 |

65 |

23 |

86 |

12.5 |

22.5 |

42 |

71 |

90.2 |

120 |

142 |

62 |

|

1/4" PT |

P95 |

G100 |

6-M18x65L |

6-M12x40L |

LYF63 |

LAF63 |

63 |

87 |

165 |

200 |

41 |

70 |

23 |

101 |

16 |

27 |

50 |

88 |

101.6 |

135 |

160 |

62 |

|

1/4" PT |

P120 |

G115 |

6-M20x70L |

6-M12x40L |

LYF80 |

LAF80 |

78 |

106 |

191 |

230 |

40 |

74 |

23 |

112 |

17 |

31 |

57 |

106 |

115.5 |

148 |

170 |

62 |

|

1/4" PT |

P145 |

G140 |

12-M20x80L |

6-M12x40L |

LYF100 |

LAF100 |

97 |

130 |

230 |

270 |

50 |

85 |

23 |

150 |

22 |

36 |

70 |

130 |

141.2 |

175 |

200 |

62 |

|

3/8" PT |

P185 |

G170 |

16-M20x90L / 16-M20x95L |

8-M12x40L |

LYF125 |

LAF125 |

128 |

170 |

260 |

298 |

58 / 65 |

82 / 105 |

23 |

185 |

32 |

43 / 45 |

89 |

160 |

167 |

200 |

223 |

70 |

|

3/8" PT |

P235 |

P235 |

16-M30x120L |

8-M16x65L |

LYF160 |

|

160 |

220 |

367 |

422 |

73 |

105 |

43 |

224 |

37 |

56 |

120 |

218 |

220 |

278 |

310 |

70 |

|

1/2" PT |

P295 |

P295 |

16-M30x120L |

10-M16x70L |

LYF200 |

|

200 |

280 |

442 |

496 |

88 |

120 |

48 |

286 |

50 |

70 |

145 |

280 |

324.5 |

366 |

394 |

85 |

|

1/2" PT |

P360 |

P360 |

20-M30x130L |

10-M16x75L |

LYF250 |

|

250 |

340 |

515 |

570 |

105 |

140 |

52 |

376 |

70 |

81 |

177 |

340 |

356.5 |

429 |

462 |

85 |

█ LYF / LAF Specification

|

Model |

Max. Pressure |

Max Flow |

Piping port |

Pilot ratio |

Gross Weight |

|

|

(Bar) |

(LPM) |

|

|

(Kg) |

||

|

|

LAF32 |

400 / 250 |

160 |

2B |

3.6 |

4.2 |

|

LYF50 |

LAF50 |

400 / 250 |

400 |

3B |

4.5 |

11.3 / 10.4 |

|

LYF63 |

LAF63 |

400 / 250 |

630 |

3.5B |

4.4 |

15 / 14 |

|

LYF80 |

LAF80 |

400 / 250 |

1000 |

4B |

4.6 |

19.5 / 18.2 |

|

LYF100 |

LAF100 |

400 / 250 |

1600 |

5B |

4.6 |

31.5 / 27.8 |

|

LYF125 |

LAF125 |

400 / 250 |

2500 |

6B |

4.5 |

42 / 43.8 |

|

LYF160 |

|

400 |

4000 |

8B |

4.3 |

108 / 118 |

|

LYF200 |

|

280 |

7000 |

12B |

4.3 |

191 |

|

LYF250 |

|

280 |

15000 |

14B |

4.5 |

295 |

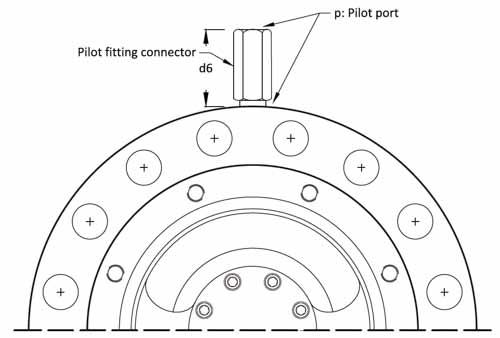

█ Pilot Port Adapter Schematic & Dimension Table

|

Model |

orifice plug |

orifice size (mm) |

|

LHF LJF LYF LAF-32 40 50 |

1/8" PT |

0.7 |

|

LHF LJF LYF LAF-63 |

0.8 |

|

|

LHF LJF LYF LAF-80 |

1.0 |

|

|

LHF LJF LYF LAF-100 |

1.2 |

|

|

LHF LJF LYF LAF-125 160 |

1/4" PT |

1.5 |

|

LHF LJF LYF LAF-200 250 |

none |

none |

█ LYF / LAF Assembly Schematic

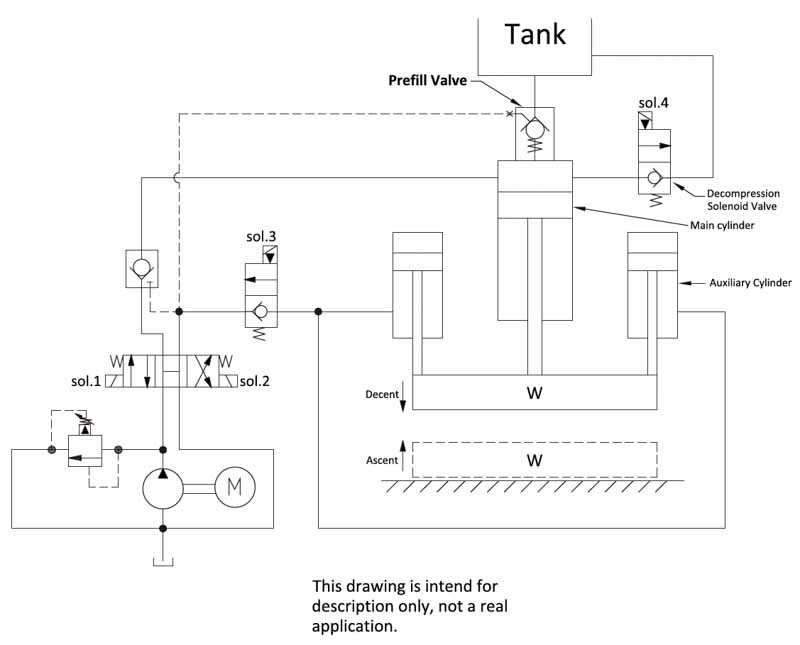

█ Application Circuit

Example of prefill valve circuit on a pressing motion.

|

Main Cylinder |

Sol.1 |

Sol.2 |

Sol.3 |

Sol.4 |

Prefill Valve |

|

rod descending |

v |

|

v |

|

suction mode |

|

chamber pressurized |

v |

|

v |

|

closed |

|

pressure retaining |

|

|

|

|

closed |

|

rod ascending |

|

v |

|

v |

pilot open |

Consideration:

1. Make sure the pressure at main cylinder cap side has completely decompression when cylinder is retracted.

2. It can connect a needle valve with decompression solenoid valve (sol.4) to control the decompression time.